Fabrication

Automated Fabrication: Versatility Tool Works and Manufacturing invests in the latest manufacturing technologies like servo-driven presses, laser cutting systems, robotics, and “lights out” automation to lower cost, improve quality, and offer the best value options to customers.

Automated Fabrication: Versatility Tool Works and Manufacturing invests in the latest manufacturing technologies like servo-driven presses, laser cutting systems, robotics, and “lights out” automation to lower cost, improve quality, and offer the best value options to customers.

Utilize the Latest, Most Advanced Prototyping and Modeling Tools (CAD-CAM, 3D Modeling, Print to Product and more)

- Invested and use Latest and Most Advanced Manufacturing Techniques and Equipment (Servo-driven Presses, Robotics, Laser Cutting and Welding, Automated Grinding and Single-Machine Automated Sheet metal Fabrication)

- Minimize or remove blanking and secondary operations

- Use Embedded Sensors in VTW Tooling to Monitor Critical Manufacturing Process Parameters

- In place ISO Quality System

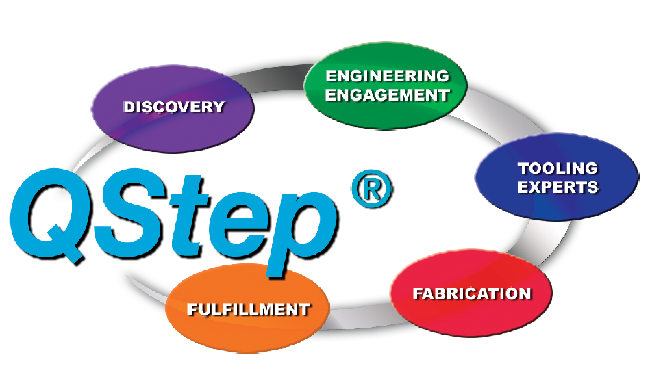

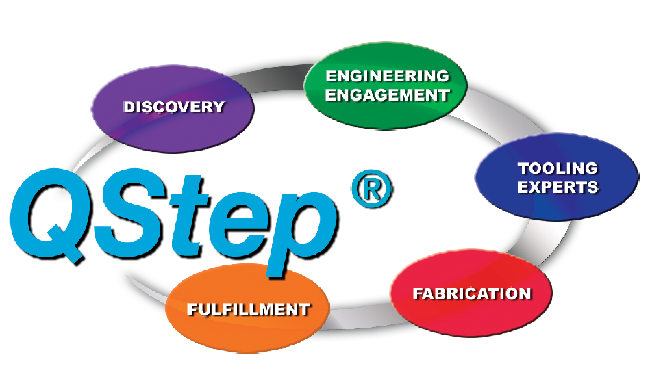

Qstep Fabrication means:

- Increasing Part Quality and Performance

- Achieving Zero Defect Production

- Removing Secondary or Combining Operations to Save Time and Reduce Cost

- Keeping Customer’s Part, Assembly or Component On Track

For more information on each step of the QStep Process and why Versatility Tool Works is the ideal metal fabricator for your manufacturing requirements, see each step below:

Call Versatility Tool Works today for a no obligation QStep Review of your problem project!

Automated Fabrication: Versatility Tool Works and Manufacturing invests in the latest manufacturing technologies like servo-driven presses, laser cutting systems, robotics, and “lights out” automation to lower cost, improve quality, and offer the best value options to customers.

Automated Fabrication: Versatility Tool Works and Manufacturing invests in the latest manufacturing technologies like servo-driven presses, laser cutting systems, robotics, and “lights out” automation to lower cost, improve quality, and offer the best value options to customers.